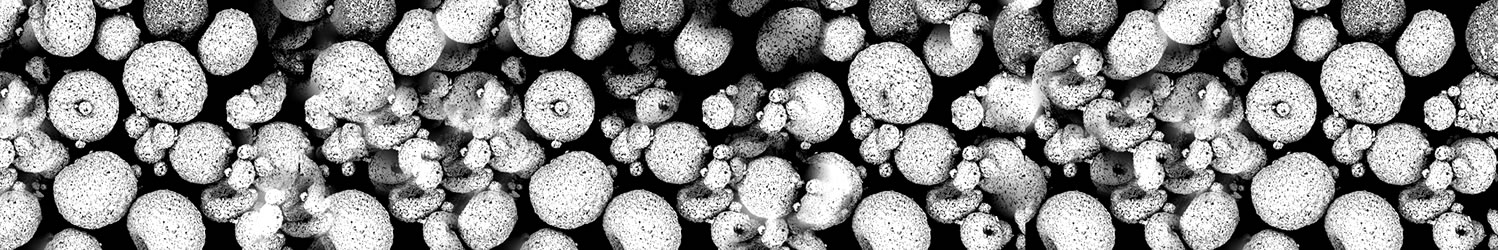

Thermal Spray Powders

CUMI is a leading manufacturer of Ceramic powders for Thermal Spray coating applications. CUMI has state of the art powder manufacturing facilities with expertise in making high quality fused, sintered and agglomerated powders. Our stringent quality and process control ensure consistent batch quality and smooth coating experience.

Good hardness, high temperature functionality and good corrosive and wear resistance characteristics make ceramic powders fit for numerous application in thermal spray coatings.

With its advanced manufacturing facilities, CUMI is renowned for providing ceramic powders with different chemistries and particle size distribution for customized solutions.

Alumina

High purity aluminum oxide is most commonly used ceramic material for thermal spray process. It has excellent dielectric and thermal resistant properties. It provides good wear resistance, chemical inertness and high temperature stability. It is used for excellent coatings on pump shafts, valves, capacitors and clearance control abrasive coating.

Alumina Titania

Alumina Titania is renowned for its excellent insulating properties and low wettability. It imparts unique properties like corrosion resistance and excellent thermal shock resistance. Titania adds toughness making it suitable for coating application in textile production tooling, hydraulic parts, shaft sleeves, mechanical seals, electrical insulations etc. CUMI provides mineral solutions with varied Titania content to impart specific properties as per the requirements.

Yttria Stabilized Zirconia

It is most commonly used material for Thermal Barrier coating. It forms an integral part of coating on turbine hot section components. Yttria is mixed in various proportions to gain unique properties. High purity and stabilization ensures good performance at high temperature.

Silicon Carbide

SiC is one of the hardest material in the world. Coating from CUMI’s Silicon Carbide provides superior coating performance in corrosive and abrasive environment as well as at high temperature.

Fused Mullite

It has low thermal conductivity and expansion coefficient. It is used for Environmental Barrier coatings and providing top coating on Ceramic Matrix compostes.

Titanium Oxide

It provides good toughness and moderate electrical conductivity making it useful in providing sliding wear resistant coatings. It is used for coating on oxygen sensors, biomedical implants and also for decorative coatings.